Having an efficient and well-designed on-premises laundry room is essential across many different industries, such as hospitality. When you build these rooms, buy equipment, and train staff, you need to give everything the proper attention it deserves to get the most significant number of benefits from these services. Read on to learn more about what to consider when designing an on-premises laundry room.

There are several variables to consider while designing your laundry room layout. You must ensure that you have enough floor space to house all necessary equipment and allow for the volume of labor required to run everything effectively. The room must primarily accommodate a range of fixed and portable equipment and accessories, such as sorting tables, folding tables, laundry carts, clothes chutes, safety, and protective equipment, as well as chemical storage.

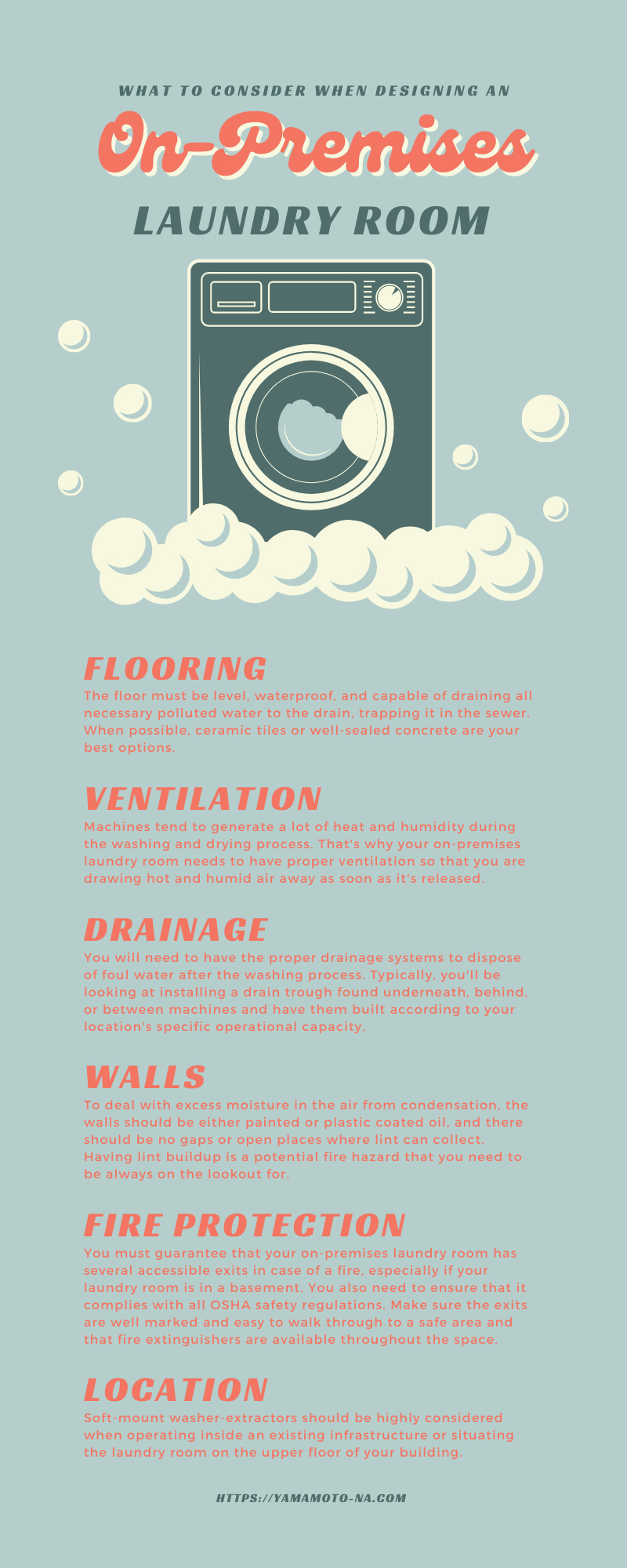

The floor must be level, waterproof, and capable of draining all necessary polluted water to the drain, trapping it in the sewer. When possible, ceramic tiles or well-sealed concrete are your best options. Although other types of flooring, such as vinyl, can be used, they will not last as long before needing repairs or replacement. Ensure that the floor can also bear the weight of the equipment and raise the machines to help with loading and draining them.

Machines tend to generate a lot of heat and humidity during the washing and drying process. That’s why your on-premises laundry room needs to have proper ventilation so that you are drawing hot and humid air away as soon as it’s released. Having the right exhaust installed will take away a good part, while an extraction fan venting to the atmosphere will remove the rest. Make sure fresh air is flowing back into the room at every step.

You will need to have the proper drainage systems to dispose of foul water after the washing process. Typically, you’ll be looking at installing a drain trough found underneath, behind, or between machines and have them built according to your location’s specific operational capacity. These troughs get made to withstand a complete dump of every device simultaneously, especially in a power outage. The draining systems will then empty directly into the plumbing, so you need to make sure your systems can effectively handle these additional loads.

To deal with excess moisture in the air from condensation, the walls should be either painted or plastic coated oil, and there should be no gaps or open places where lint can collect. Having lint buildup is a potential fire hazard that you need to be always on the lookout for. You should be able to install machines near walls without issue as well, such as oddly shaped enclosures or partitions.

You must guarantee that your on-premises laundry room has several accessible exits in case of a fire, especially if your laundry room is in a basement. You also need to ensure that it complies with all OSHA safety regulations. Make sure the exits are well marked and easy to walk through to a safe area and that fire extinguishers are available throughout the space. You should install a fully automated sprinkler system that responds promptly to danger, as well as placing smoke detectors near tumble driers and where freshly dried linens are stored. You should fully train employees in fire safety protocols to know precisely what to do if a fire breaks out.

Your location can play a big hand in deciding what equipment you will use. When starting construction from the ground up, you should aim for thick cement for your flooring. Furthermore, this flooring should rest on compacted earth and avoid building on top of existing structures to have the option of using hard-mount washer-extractors.

By mounting the washers on stable, concrete flooring, you will significantly reduce the number of vibration-control parts needed. Having fewer components generally means fewer parts that need to be supported and repaired, saving you money and downtime.

Soft-mount washer-extractors should be highly considered when operating inside an existing infrastructure or situating the laundry room on the upper floor of your building. These machines feature stabilizing components that carry minimal vibration down the floor, allowing them to be put almost anywhere without irritating neighbors, employees, or customers on all sides of the laundry room. Therefore, once you’ve determined your possible site, you can begin arranging for the equipment you’ll need.

The final design decisions you choose will largely determine parts of your training with employees. For example, different machines will have different ideal detergent mixes and wash settings. You will also want to make sure every staff member is using the space as efficiently as possible, whether it’s a system for loading and unloading carts or finding the best possible storage space that is easy to access.

You will also need to consider all the safety measures you will need to put in place that can affect your design and ensure all employees are well versed in proper practices. Create written processes and techniques for how to conduct laundry tasks, particularly laundry collecting and organizing. This will streamline the training process, prevent linens from being lost or damaged, and make everyone’s job a little easier.

One of the best ways to start your on-premises laundry room design is to consult with laundry service representatives who are highly knowledgeable about what type of machines and layouts will work best with your industry needs. Your distributor will give you advice throughout the process to ensure that you have the best possible setup to run your laundry services efficiently. You’ll be able to make decisions on machines more confidently and trust that your linens, garments, and customer clothing is in safe hands.

Hopefully, this guide can help you when you’re looking for what to consider when designing an on-premises laundry room. The best place to start is working with trusted laundry equipment professionals like the experts at Yamamoto. Yamamoto is family-owned and managed in Hiroshima, Japan, and has produced laundry equipment for more than 70 years.

We can provide an industrial-strength washer and dryer that has all the benefits of a split system with half the size requirements. They are perfect when you are designing an on-premises laundry room and want to fit in more machines or have extra space available while still meeting your needs. Feel free to contact us with any questions about our products.